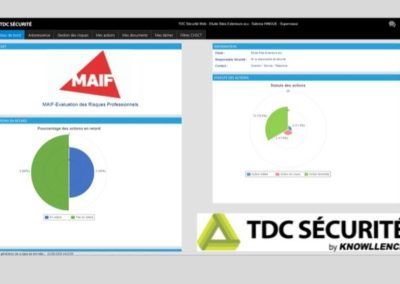

Quelques client·e·s qui nous font confiance…

Ce sont nos client·e·s qui parlent le mieux de nos logiciels et de nos prestations de formation/conseil !

Plutôt que d’afficher une simple collection de logos, nous préférons donner la parole à nos utilisateurs et à nos utilisatrices.

Les témoignages ci-dessous ont été collectés progressivement, et les vidéos ont généralement été tournées à l’occasion des réunions de nos Clubs Utilisateurs.